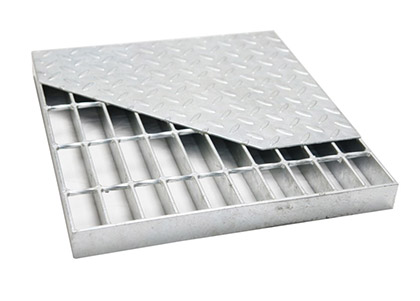

Composite steel grating for mining applications has become an essential component in the mining industry. These gratings are designed to provide a durable, safe, and efficient walking surface for workers while also allowing for the drainage of water and debris. The unique properties of composite steel grating make it ideal for the harsh environments found in mining operations, where traditional materials may fail under pressure.

One of the primary advantages of composite steel grating for mining applications is its lightweight nature. This feature allows for easier handling and installation, reducing labor costs and downtime during maintenance. Additionally, the lightweight design does not compromise strength, as these gratings can withstand heavy loads and extreme conditions, making them a reliable choice for various mining tasks.

Durability is another critical factor when considering composite steel grating for mining applications. These gratings are resistant to corrosion, rust, and other environmental factors that can degrade traditional steel materials. This resistance ensures a longer lifespan for the grating, ultimately leading to lower replacement costs and less frequent maintenance schedules, which is crucial in the mining industry where time is money.

Safety is paramount in mining operations, and composite steel grating plays a significant role in enhancing workplace safety. The slip-resistant surface of these gratings provides excellent traction, reducing the risk of slips and falls, which are common hazards in mining environments. This feature not only protects workers but also helps to maintain productivity levels by minimizing accidents and associated downtime.

Another important aspect of composite steel grating for mining applications is its versatility. These gratings can be customized to fit various applications, including walkways, platforms, and even stair treads. This adaptability makes them suitable for different mining operations, whether they involve surface mining or underground activities. The ability to tailor the grating to specific needs ensures maximum efficiency and safety in all aspects of mining work.

Environmental considerations are increasingly important in the mining sector, and composite steel grating aligns with sustainable practices. Many manufacturers produce these gratings using recycled materials, which helps reduce the carbon footprint associated with mining operations. By choosing composite steel grating, mining companies can demonstrate their commitment to environmental stewardship while also benefiting from the functional advantages these products offer.

In terms of maintenance, composite steel grating for mining applications requires minimal upkeep compared to traditional materials. The inherent properties of composite materials mean that they do not need painting or regular treatment to maintain their integrity. This low-maintenance requirement allows mining companies to focus their resources on more critical operational areas, improving overall efficiency and productivity in the workplace.

The installation process for composite steel grating is straightforward, further enhancing its appeal for mining applications. The lightweight design and modular nature of these gratings allow for quick assembly and disassembly, making it easier to adapt to changing site conditions. This flexibility is especially beneficial in mining operations where layouts may need to change frequently due to excavation or other factors.

Cost-effectiveness is a significant consideration for mining companies when selecting materials. While the initial investment in composite steel grating may be higher than traditional steel options, the long-term savings from reduced maintenance, increased safety, and extended lifespan make it a wise choice. Companies can realize substantial cost benefits over time, making composite steel grating a smart investment for mining applications.

As the mining industry continues to evolve, the demand for innovative materials like composite steel grating is likely to grow. Advances in technology and manufacturing processes are leading to the development of even more robust and efficient grating solutions. Staying ahead of these trends will be crucial for mining companies looking to maintain a competitive edge in a challenging market.

In summary, composite steel grating for mining applications offers numerous advantages, including durability, safety, and cost-effectiveness. Its lightweight design and low maintenance requirements make it an ideal choice for the demanding conditions of mining environments. As the industry progresses, the role of composite materials will likely expand, providing even more solutions for modern mining challenges.

When selecting composite steel grating, it is essential to consider factors such as load capacity, environmental conditions, and specific application requirements. Consulting with manufacturers and suppliers can help ensure that the right type of grating is chosen for each unique situation. This tailored approach will maximize the benefits of composite steel grating, leading to safer and more efficient mining operations.

In addition to the practical benefits of composite steel grating, there are also aesthetic considerations. These gratings can be manufactured in various colors and finishes, allowing mining companies to maintain a professional appearance on their sites. This attention to detail can enhance the overall image of the company and contribute to a positive workplace culture.

Moreover, the installation of composite steel grating can be an opportunity to implement safety training initiatives. By involving workers in the installation process, companies can educate them on the importance of safety and proper use of equipment. This proactive approach to safety can foster a culture of awareness and responsibility among employees, further reducing the risk of accidents.

The global demand for resources is constantly rising, placing additional pressure on the mining industry to operate efficiently and sustainably. Composite steel grating for mining applications addresses some of these challenges by providing a solution that enhances operational efficiency while minimizing environmental impact. As mining companies seek to balance productivity with sustainability, the adoption of advanced materials like composite steel grating will be crucial.

Future innovations in composite materials may lead to even more advanced grating solutions tailored for specific mining applications. Research into new composites and manufacturing techniques could result in products that offer enhanced performance characteristics, such as increased load-bearing capacity or improved resistance to extreme temperatures. Staying informed about these developments will be essential for mining companies looking to leverage the latest technologies.

In conclusion, composite steel grating for mining applications is a versatile and effective solution that addresses many of the challenges faced by the industry today. Its combination of durability, safety, and cost-effectiveness makes it a preferred choice for mining operations worldwide. As the industry continues to evolve, embracing innovative materials will be key to ensuring a successful future for mining companies.

Overall, the integration of composite steel grating into mining operations represents a significant step forward in improving safety, efficiency, and sustainability. By investing in high-quality grating solutions, mining companies can enhance their operational capabilities while also contributing to a safer work environment for their employees.