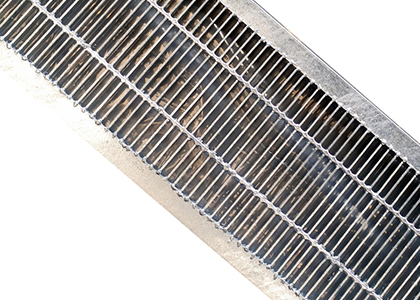

Narrow pitch grating for lab work surfaces is an essential component in modern laboratory environments. These gratings are designed to provide optimal performance in various applications, ensuring that laboratory work surfaces are both functional and efficient. The unique design of narrow pitch gratings allows for better light management, making them ideal for optical applications and enhancing experimental results.

One of the primary benefits of using narrow pitch grating for lab work surfaces is their ability to minimize light scattering. This characteristic is particularly important in laboratories that rely on precise measurements and observations. With reduced scattering, researchers can achieve higher accuracy in their experiments, leading to more reliable data and conclusions.

In addition to their optical advantages, narrow pitch gratings also offer excellent durability and resistance to chemical exposure. Laboratories often deal with a variety of substances, some of which can be corrosive or damaging to standard materials. By incorporating narrow pitch gratings into lab work surfaces, facilities can ensure longevity and maintain a safe working environment for researchers and technicians alike.

The manufacturing process of narrow pitch gratings involves advanced techniques that ensure high precision and quality. These gratings are typically produced using photolithography or etching methods, which allow for the creation of fine grooves with specific pitches. This level of precision is crucial for applications requiring exact specifications, such as spectroscopy or microscopy.

When selecting narrow pitch grating for lab work surfaces, it is essential to consider factors such as the material, groove depth, and pitch. Different materials offer varying levels of performance and durability, so understanding the specific needs of your laboratory is critical. For example, glass gratings may be preferred for certain optical applications, while metal gratings might be more suitable for environments with harsh chemicals.

Another important consideration is the alignment and installation of narrow pitch gratings. Proper alignment ensures that the grating performs optimally, reducing errors in measurements and enhancing the overall efficiency of laboratory processes. Many manufacturers provide guidelines for installation, and it is advisable to follow these closely to achieve the best results.

In laboratories that require high-resolution imaging, narrow pitch gratings play a vital role in enhancing the quality of images captured. By reducing aberrations and improving light transmission, these gratings contribute to clearer and more detailed images, which are essential for research and analysis. This improvement can significantly impact the outcomes of experiments, especially in fields such as biology and materials science.

The versatility of narrow pitch gratings makes them suitable for a wide range of laboratory applications. From analytical chemistry to biomedical research, these gratings can be adapted to meet the specific needs of various experiments. Their ability to provide consistent performance across different conditions is a key factor in their popularity among researchers.

As laboratories continue to evolve and adopt new technologies, the demand for narrow pitch grating for lab work surfaces is expected to grow. Innovations in material science and fabrication techniques will likely lead to even more advanced gratings, further enhancing their performance and applications. Staying updated on these developments is crucial for laboratory managers and researchers alike.

In summary, narrow pitch grating for lab work surfaces is a fundamental element that contributes to the efficiency and effectiveness of laboratory operations. By understanding the benefits and considerations associated with these gratings, laboratories can make informed decisions that enhance their research capabilities. As technology advances, the integration of narrow pitch gratings will continue to play a significant role in the future of scientific research.

The cost of narrow pitch grating for lab work surfaces can vary depending on several factors, including the material and manufacturing process. While it may be tempting to opt for lower-cost alternatives, investing in high-quality gratings can lead to long-term savings by reducing the need for replacements and ensuring consistent performance. It is essential to weigh the initial costs against the potential benefits when making purchasing decisions.

Laboratory managers should also consider the maintenance requirements of narrow pitch gratings. Regular cleaning and inspection can help prolong their lifespan and maintain optimal performance. Depending on the laboratory environment, specific cleaning agents and techniques may be recommended to avoid damaging the gratings.

Training staff on the proper handling and usage of narrow pitch gratings is another crucial aspect of maintaining their effectiveness. Ensuring that all personnel understand the importance of these components and how to care for them can lead to better outcomes in laboratory work. This training can include best practices for installation, cleaning, and troubleshooting common issues.

Moreover, collaboration with manufacturers can provide laboratories with valuable insights into the latest advancements in narrow pitch grating technology. Many manufacturers offer technical support and resources that can aid in selecting the right grating for specific applications. Establishing a good relationship with suppliers can also lead to better pricing and access to exclusive products.

As research becomes increasingly interdisciplinary, the applications of narrow pitch grating for lab work surfaces are expanding. Fields such as nanotechnology and photonics are discovering new ways to utilize these gratings, leading to innovative experimental designs and breakthroughs. Keeping abreast of these trends can position laboratories at the forefront of scientific discovery.

In conclusion, narrow pitch grating for lab work surfaces is a critical component that enhances the functionality and efficiency of laboratory environments. By understanding their benefits, selecting the right materials, and maintaining them properly, laboratories can ensure they are equipped to handle the demands of modern research. As technology continues to advance, the role of these gratings will undoubtedly grow, making them an indispensable part of future laboratory designs.

The integration of narrow pitch gratings into lab work surfaces is not just about performance; it also reflects a commitment to quality and innovation in scientific research. As laboratories strive for excellence, the choice of materials and components becomes increasingly important. Narrow pitch gratings represent a step towards achieving higher standards in laboratory work.

Furthermore, the environmental impact of laboratory materials is an important consideration for many institutions today. Choosing sustainable options for narrow pitch grating can contribute to a laboratory’s overall green initiatives. By selecting manufacturers that prioritize eco-friendly practices, laboratories can align their operations with contemporary sustainability goals.

In closing, the future of narrow pitch grating for lab work surfaces looks promising. With ongoing research and development, we can expect to see enhancements that not only improve performance but also address environmental and economic concerns. Laboratories that invest in these technologies will be better positioned to tackle the challenges of tomorrow’s scientific landscape.