In the world of construction and infrastructure projects, the installation of standard steel grating is a task of utmost importance. It demands meticulous attention to detail and strict compliance with specific guidelines to guarantee both safety and optimal functionality. When it comes to standard steel grating installation instructions, XINXING GRATING, a company with a rich and distinguished history, has a wealth of expertise to offer.

XINXING GRATING traces its roots back to 1971 when it originated from the 2672 Engineering Headquarters of the People’s Liberation Army. Later, in 1997, it was listed on the Shenzhen Stock Exchange. As the core enterprise of Xinxing International Group, supervised by the State – owned Assets Supervision and Administration Commission of the State Council (SASAC), XINXING GRATING has firmly established itself as an international leader in the manufacturing of pressed – welded steel gratings, their accessories, and various types of platform railings.

The initial and crucial step in standard steel grating installation, as per XINXING GRATING’s recommendations, is to conduct a comprehensive site inspection. This involves a detailed assessment of the ground conditions. For instance, in industrial settings where XINXING GRATING’s steel gratings are often used, like petrochemical plants or municipal engineering projects, checking for any potential obstacles is essential. In a petrochemical plant, there could be pipelines or other equipment that might interfere with the installation. Ensuring that the area is clear and ready for installation is the foundation for a successful project. Proper site preparation not only prevents future issues but also significantly contributes to the long – term durability of XINXING GRATING’s high – quality steel gratings.

Once the site is thoroughly prepared, the next phase in following the standard steel grating installation instructions is to gather all the necessary tools and materials. XINXING GRATING provides a wide range of standard steel grating panels, along with the appropriate fasteners and any additional support structures required for different applications. Their annual production capacity of 120,000 tons of steel grating and accessories ensures that projects of all scales can be supplied without delay. Having all materials on – hand before commencing the installation process is crucial. This not only avoids costly delays but also ensures a seamless workflow. The company emphasizes the use of correct tools, such as wrenches, drills, and high – precision measuring tapes, to guarantee precision and accuracy during the installation of their standard steel gratings.

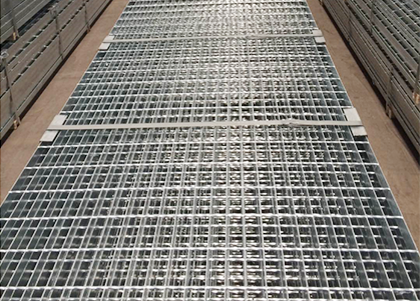

After assembling all the materials, the layout of XINXING GRATING’s standard steel grating needs to be planned with great care. This begins with accurately measuring the area where the grating will be installed. Whether it’s a large – scale industrial project or a small – scale municipal application, precise measurements are non – negotiable. In a large – scale factory installation, for example, mismeasurements could lead to significant problems in the overall structure. Marking the positions where each panel will be placed is also a critical step. Standard steel grating installation instructions provided by XINXING GRATING typically recommend double – checking all measurements before proceeding to the next step. This simple yet effective practice helps avoid costly mistakes and rework. Proper alignment and spacing of the grating panels are essential, not only for the aesthetic appeal of the final installation but also for ensuring the functionality of the steel grating. XINXING GRATING’s gratings, with their customizable flat steel sizes ranging from 193mm to 15010mm and spacing options from 12.5mm to 100mm, can be tailored to fit any project’s specific requirements during the layout planning.

XINXING GRATING’s manufacturing capabilities play a significant role in the standard steel grating installation process. Since introducing Japan’s fully automatic steel grating production line in 1994, which has been continuously optimized over the years, the company now has an extensive production infrastructure. With 4 flat steel production lines, 17 advanced pressure welding production lines, and 3 hot – dip galvanizing production lines, they can ensure that the steel gratings used in installations are of the highest quality. The company’s independent intellectual property rights for the R&D and design of pressure welding machines, along with its nationally recognized enterprise technology R&D center and post – doctoral mobile workstation, are constantly working on improving the performance of their products. As an integrated supplier, covering every aspect from equipment R&D to flat steel production, grating processing, hot – dip galvanizing, and railway logistics, XINXING GRATING can offer comprehensive support throughout the standard steel grating installation project.

Moreover, as one of the major drafters of the steel gratings industry standard YB/T4001.1 – 2019, XINXING GRATING sets the benchmark for quality and performance. Their standard steel grating products are widely used across more than 30 countries and regions worldwide, with a leading domestic market share. When following their standard steel grating installation instructions, customers can be confident that they are using products and procedures that meet the highest industry standards.

Upholding the tenet of “quality first, customer first,” XINXING GRATING is committed to providing customers with not only top – notch standard steel grating products but also detailed and reliable installation instructions. By adhering to the value concept of win – win cooperation and co – creation and sharing, the company aims to build long – term partnerships with customers. Whether it’s a small local project or a large – scale international endeavor, XINXING GRATING has the expertise, advanced manufacturing capabilities, and unwavering dedication to ensure that the installation of their standard steel gratings is carried out smoothly, guaranteeing the seamless operation and long – term integrity of the installed structures.