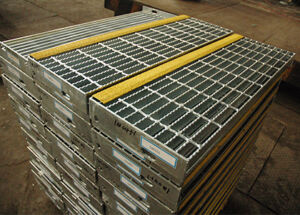

Flat steel grating and serrated steel grating are two common types of steel grating used in various applications. Both have their own unique characteristics and advantages, making them suitable for different purposes.

Flat steel grating is manufactured by a series of flat steel bars that are placed at equal distances and then welded together. This results in a smooth and flat surface, making it ideal for applications where slip resistance is not a major concern. On the other hand, serrated steel grating is designed with serrated teeth on the surface of the bearing bars, providing excellent slip resistance, making it suitable for areas where safety is a priority, such as industrial walkways and ramps.

When it comes to load-bearing capacity, flat steel grating and serrated steel grating also have differences. Flat steel grating is known for its high strength and load-bearing capacity, making it suitable for heavy-duty applications such as industrial flooring, 木平台和覆盖水泥地面, and trench covers. On the other hand, serrated steel grating is also capable of supporting heavy loads, but its serrated surface provides additional grip, making it more suitable for areas where slip resistance is essential.

In terms of appearance, flat steel grating and serrated steel grating also differ. Flat steel grating has a clean and uniform look, making it suitable for architectural applications where aesthetics are important. Serrated steel grating, on the other hand, has a rugged and industrial look due to its serrated surface, making it ideal for industrial and commercial settings where functionality is prioritized over appearance.

When it comes to maintenance, both types of steel grating are relatively low maintenance. However, the serrations on serrated steel grating may require more frequent cleaning to prevent debris buildup, especially in outdoor or high-traffic areas. Flat steel grating, on the other hand, is easier to clean and maintain due to its smooth surface, making it suitable for applications where hygiene is a concern.

In conclusion, both flat steel grating and serrated steel grating have their own unique characteristics and advantages. The choice between the two depends on the specific requirements of the application, such as load-bearing capacity, slip resistance, appearance, and maintenance needs.