Floor plate steel grating installation in workshops is a critical process that ensures safety and efficiency in industrial environments. The use of steel grating provides a durable, slip-resistant surface that can withstand heavy loads, making it ideal for various applications. Dalam artikel ini, we will explore the detailed steps involved in the installation of floor plate steel grating, the materials required, and the benefits of using this type of flooring in workshops.

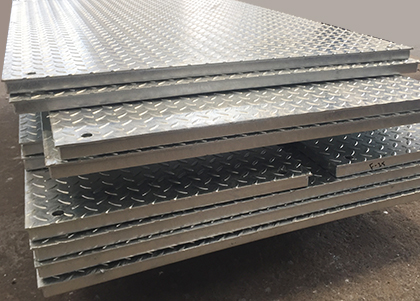

Before diving into the installation process, it’s essential to understand the different types of floor plate steel grating available on the market. Common types include welded grating, jeriji terkunci tekan, and swage-locked grating. Each type has its unique features and benefits, tailored for specific applications in workshops. Understanding these differences will help you make an informed decision when selecting the right grating for your needs.

The first step in the floor plate steel grating installation in workshops is to assess the area where the grating will be installed. This involves measuring the dimensions of the workspace, noting any obstacles, and determining the load requirements. Proper assessment ensures that the selected grating will fit perfectly and meet the necessary safety standards.

Once the assessment is complete, the next step is to gather all the necessary materials and tools for the installation. Essential materials include the steel grating itself, support beams, anchors, and safety equipment. Tools such as a measuring tape, level, saw, and drill will also be required. Having all materials on hand before starting the installation will streamline the process and minimize delays.

Before proceeding with the installation, it’s crucial to prepare the workspace. This includes clearing the area of any debris and ensuring that the subfloor is level and free from moisture. A clean and dry surface is vital for the proper installation of floor plate steel grating, as it helps to prevent future issues such as rust and instability.

With the workspace prepared, the next step is to install the support beams. These beams will provide the necessary support for the steel grating and must be installed according to the manufacturer’s specifications. It’s important to ensure that the beams are level and securely anchored to the floor to provide a stable foundation for the grating.

After the support beams are in place, the installation of the floor plate steel grating can begin. Start by laying the first piece of grating onto the support beams, ensuring that it fits snugly and is properly aligned. It’s essential to follow the manufacturer’s guidelines regarding spacing and placement to ensure safety and functionality.

As you continue to install the grating, be sure to check for levelness and alignment regularly. Using a level tool can help ensure that each piece of grating is installed correctly. Any misalignment can lead to safety hazards and may require reinstallation, which can be time-consuming and costly.

Once all pieces of floor plate steel grating have been installed, the final step is to secure them in place. This often involves using anchors or fasteners to hold the grating down firmly. Properly securing the grating is crucial for preventing movement and ensuring the safety of individuals working in the area.

In addition to safety, floor plate steel grating offers several advantages in workshop environments. Its open design allows for excellent drainage, preventing water accumulation that can lead to slips and falls. Additionally, the durability of steel grating means it can withstand heavy machinery and foot traffic without significant wear and tear.

Another benefit of using floor plate steel grating is its low maintenance requirements. Unlike traditional flooring materials that may require regular waxing or sealing, steel grating can be easily cleaned with a broom or pressure washer. This makes it an ideal choice for busy workshops where time is of the essence.

It’s also worth noting that floor plate steel grating is available in various finishes, including galvanized and painted options. These finishes not only enhance the aesthetic appeal of the workspace but also provide additional protection against corrosion and wear. Selecting the right finish can extend the lifespan of the grating and maintain its appearance over time.

When considering floor plate steel grating installation in workshops, it’s essential to factor in the overall cost. While the initial investment may be higher than other flooring options, the long-term benefits often outweigh the costs. The durability, safety, and low maintenance of steel grating can lead to significant savings over time.

Kesimpulannya, the installation of floor plate steel grating in workshops is a process that requires careful planning and execution. By understanding the types of grating available, preparing the workspace, and following the proper installation steps, you can ensure a safe and efficient working environment. The benefits of using steel grating, including durability, low maintenance, and safety, make it an excellent choice for any workshop.

Whether you are upgrading an existing workshop or building a new one, consider the advantages of floor plate steel grating. Its robust design and slip-resistant surface can enhance safety and productivity in any industrial setting. With the right installation process, you can enjoy the benefits of this flooring solution for years to come.

For those considering the DIY approach to floor plate steel grating installation, it’s important to educate yourself on the process thoroughly. While it can be a rewarding project, safety should always be your top priority. Ensure you have the right tools and materials, and don’t hesitate to seek professional assistance if needed.

Ringkasnya, floor plate steel grating installation in workshops is not just about laying down a floor; it’s about creating a safe and efficient working environment. By following the steps outlined in this article, you can achieve a successful installation that meets your workshop’s needs and enhances overall productivity.