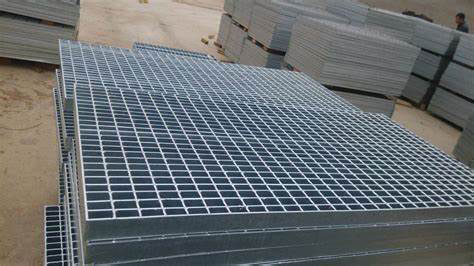

When it comes to choosing between galvanized steel grating and stainless steel grating, there are several factors to consider. Galvanized steel grating is coated with a layer of zinc, which provides excellent corrosion resistance and durability. On the other hand, stainless steel grating is made from an alloy of steel, chromium, and sometimes nickel, offering superior resistance to corrosion and heat. Both types of grating have their own advantages and disadvantages, and it’s important to understand the differences before making a decision.

One of the key differences between galvanized steel grating and stainless steel grating is their corrosion resistance. Galvanized steel grating is well-known for its ability to withstand harsh environmental conditions, making it ideal for outdoor applications. The zinc coating acts as a barrier against moisture, preventing rust and corrosion. Stainless steel grating, on the other hand, contains chromium, which forms a thin oxide layer on the surface, providing protection against rust and corrosion. This makes stainless steel grating suitable for environments with high humidity and exposure to corrosive elements.

In terms of strength and load-bearing capacity, both galvanized steel grating and stainless steel grating are highly durable and capable of supporting heavy loads. Galvanized steel grating is known for its strength and resilience, making it a popular choice for industrial and commercial settings. The zinc coating enhances the structural integrity of the grating, allowing it to withstand heavy foot traffic and vehicular loads. Stainless steel grating is also renowned for its strength and durability, thanks to the alloy composition. It is particularly well-suited for applications that require resistance to impact and heavy loads.

Another important consideration when comparing galvanized steel grating and stainless steel grating is their maintenance requirements. Galvanized steel grating is relatively low maintenance, requiring only occasional cleaning to remove dirt and debris. The zinc coating provides long-term protection against corrosion, reducing the need for frequent maintenance. Stainless steel grating is also easy to maintain, as it is resistant to staining and corrosion. Regular cleaning with mild soap and water is usually sufficient to keep stainless steel grating in top condition.

Cost is a significant factor to consider when choosing between galvanized steel grating and stainless steel grating. Galvanized steel grating is generally more affordable than stainless steel grating, making it a cost-effective option for many applications. The initial lower cost of galvanized steel grating can result in substantial savings, especially for large-scale projects. Stainless steel grating, while more expensive upfront, offers long-term cost benefits due to its durability and longevity. It is important to weigh the initial investment against the expected lifespan and maintenance costs when making a decision.

In conclusion, the choice between galvanized steel grating and stainless steel grating depends on the specific requirements of the application. Galvanized steel grating is an excellent option for outdoor and industrial settings, offering corrosion resistance and strength at a lower cost. Stainless steel grating is ideal for environments with high humidity and corrosive elements, providing superior durability and a modern aesthetic. By carefully evaluating the factors of corrosion resistance, strength, maintenance, and cost, you can determine the best type of grating for your project.