Heavy duty trench cover is an essential part of urban infrastructure, providing safety and accessibility for pedestrians and vehicles. These covers are designed to withstand heavy loads and harsh environmental conditions, making them ideal for use in busy urban areas and industrial sites.

The material used for heavy duty trench covers is typically high-strength steel or ductile iron, ensuring durability and long-term performance. The covers are often designed with anti-slip surfaces to prevent accidents caused by slippery conditions, further enhancing safety for pedestrians and vehicles.

One of the key considerations when choosing heavy duty trench covers is the load rating. Different covers are designed to support varying weights, so it’s important to select the appropriate cover based on the expected traffic and load requirements. Additionally, proper installation and maintenance are crucial for ensuring the optimal performance and longevity of the trench covers.

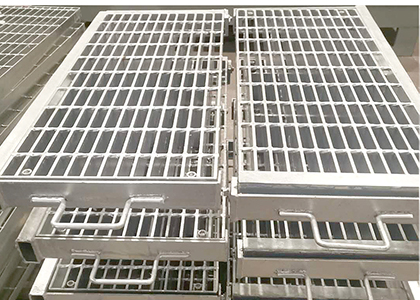

Heavy duty trench covers are available in various sizes and configurations to accommodate different trench dimensions and load requirements. Some covers are designed for pedestrian foot traffic, while others are suitable for heavy vehicle loads. It’s essential to consider the specific application and traffic conditions when selecting the right trench cover for a particular location.

In addition to load-bearing capabilities, heavy duty trench covers are also designed to resist corrosion and wear, especially in outdoor environments where they are exposed to moisture, chemicals, and other corrosive elements. Protective coatings and materials are often applied to enhance the covers’ resistance to rust and deterioration, prolonging their service life.

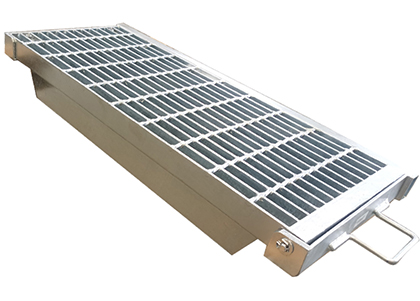

When it comes to installation, heavy duty trench covers should be securely fitted to prevent displacement and ensure stability. Proper installation techniques, such as using anchoring systems and secure fastening, are essential for maintaining the integrity of the covers and preventing hazards caused by loose or unstable trench covers.

Regular inspection and maintenance of heavy duty trench covers are necessary to identify any signs of damage, wear, or corrosion. Prompt repairs and replacements should be carried out to address any issues and prevent safety hazards. Routine cleaning and debris removal are also important for keeping the covers in optimal condition.

The design of heavy duty trench covers is crucial for achieving a balance between strength, durability, and aesthetic appeal. Modern trench cover designs often incorporate sleek and streamlined profiles, blending seamlessly with the surrounding urban landscape while meeting the functional requirements for safety and load-bearing capacity.

In urban environments, heavy duty trench covers play a critical role in ensuring the smooth flow of pedestrian and vehicular traffic. Properly installed and well-maintained trench covers contribute to the overall safety and accessibility of sidewalks, roadways, and public spaces, enhancing the quality of urban infrastructure.

In industrial settings, heavy duty trench covers are essential for protecting underground utility access points and ensuring the safety of workers and equipment. These covers are designed to withstand the heavy loads and harsh conditions commonly found in industrial facilities, providing reliable access solutions for maintenance and operations.

The selection of heavy duty trench covers should take into account the specific requirements of the application, including load ratings, dimensions, material properties, and environmental factors. Consulting with experienced engineers and suppliers can help in identifying the most suitable trench cover solutions for different projects and locations.

In summary, heavy duty trench covers are indispensable components of urban and industrial infrastructure, offering robust solutions for safety, accessibility, and load-bearing performance. By selecting the right trench covers, ensuring proper installation and maintenance, and considering the specific application requirements, urban planners, engineers, and facility managers can effectively enhance the functionality and safety of their infrastructure.

The installation of heavy duty trench covers is a critical aspect of ensuring their performance and safety. Proper installation techniques, including the use of anchoring systems and secure fastening, are essential for preventing displacement and instability of the covers. Additionally, following the manufacturer’s guidelines and recommendations for installation can help in maximizing the longevity and reliability of the trench covers.

Regular inspection and maintenance of heavy duty trench covers are essential for identifying any signs of wear, damage, or corrosion. Prompt repairs and replacements should be carried out to address any issues and prevent safety hazards. Routine cleaning and debris removal are also important for preserving the covers’ functionality and appearance.

The material used for heavy duty trench covers is a critical factor in determining their durability and performance. High-strength steel and ductile iron are commonly utilized materials, known for their exceptional load-bearing capabilities and resistance to wear and corrosion. These materials undergo rigorous testing and quality control to ensure compliance with industry standards and specifications.

The load rating of heavy duty trench covers is an important consideration when selecting the appropriate cover for a specific application. Different covers are designed to support varying weights, ranging from pedestrian foot traffic to heavy vehicle loads. Understanding the expected traffic conditions and load requirements is crucial for choosing the right trench cover that can safely and effectively meet the application’s needs.

In addition to load-bearing capabilities, heavy duty trench covers are often designed with anti-slip surfaces to enhance safety for pedestrians and vehicles. These surfaces provide traction and stability, reducing the risk of accidents caused by slippery conditions. Anti-slip features are particularly important in areas exposed to moisture, oil, or other slippery substances.

The design and configuration of heavy duty trench covers are tailored to accommodate various trench dimensions and load requirements. Whether it’s a narrow pedestrian walkway or a wide roadway exposed to heavy traffic, there are trench cover options available to meet the specific needs of different applications. Customization and versatility in design allow for seamless integration with diverse urban and industrial environments.

Corrosion resistance is a key feature of heavy duty trench covers, especially in outdoor environments where they are exposed to moisture, chemicals, and other corrosive elements. Protective coatings and materials, such as galvanization and epoxy coatings, are applied to the covers to enhance their resistance to rust and deterioration, ensuring long-term durability and performance.

The aesthetic appeal of heavy duty trench covers is an important consideration for urban environments, where infrastructure design and appearance play a significant role in enhancing the overall urban landscape. Modern trench cover designs often feature sleek and contemporary profiles, complementing the surrounding architecture and public spaces while meeting the functional requirements for safety and accessibility.

The role of heavy duty trench covers in urban infrastructure is vital for ensuring the safety and accessibility of sidewalks, roadways, and public spaces. Properly selected and well-maintained trench covers contribute to the smooth flow of pedestrian and vehicular traffic, minimizing safety risks and enhancing the overall quality of urban environments. By addressing the specific load and safety requirements, urban planners and engineers can effectively integrate trench covers into their infrastructure designs.

In industrial facilities, heavy duty trench covers are essential for safeguarding underground utility access points and ensuring the safety of workers and equipment. These covers are designed to withstand heavy loads and harsh conditions, providing reliable access solutions for maintenance and operations. By selecting trench covers that meet the specific load and environmental requirements, facility managers can enhance the safety and functionality of their industrial infrastructure.

The selection of heavy duty trench covers involves careful consideration of load ratings, dimensions, material properties, and environmental factors to ensure optimal performance and safety. Consulting with experienced engineers, manufacturers, and suppliers can provide valuable insights and recommendations for selecting the most suitable trench cover solutions for different projects and locations. By leveraging expertise and industry knowledge, stakeholders can make informed decisions that align with their specific application needs.

In conclusion, heavy duty trench covers are indispensable components of urban and industrial infrastructure, offering robust solutions for safety, accessibility, and load-bearing performance. By understanding the key factors influencing the selection, installation, and maintenance of trench covers, stakeholders can effectively enhance the functionality and safety of their infrastructure, contributing to the overall quality and reliability of urban and industrial environments.