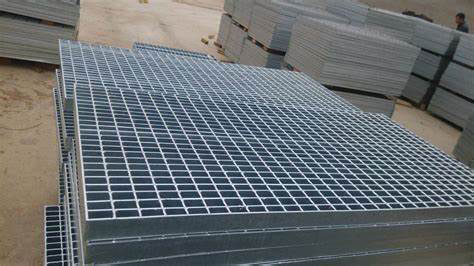

Maintaining steel grating is essential for ensuring its longevity and optimal performance. Regular cleaning, inspection, and maintenance are key to preventing corrosion, extending the lifespan of the grating, and ensuring the safety of the surrounding environment. In this comprehensive guide, we will discuss various methods and best practices for maintaining steel grating in different environments and applications. Whether it’s industrial facilities, commercial buildings, or public infrastructure, proper maintenance of steel grating is crucial for safety and efficiency.

To maintain steel grating, start by regularly cleaning the surface to remove dirt, debris, and other contaminants. This can be done using a mild detergent, water, and a brush or pressure washer. It’s important to remove any buildup of substances that can lead to corrosion or compromise the structural integrity of the grating. In addition to regular cleaning, inspections should be conducted to identify any signs of wear, damage, or corrosion. This includes checking for loose or broken bars, rust formation, and any structural irregularities. By addressing these issues early, you can prevent further damage and ensure the long-term performance of the steel grating.

In industrial settings, steel grating is often exposed to harsh conditions that can accelerate corrosion and wear. As such, it’s important to implement a proactive maintenance plan that includes regular inspections, cleaning, and protective coatings. This can help mitigate the impact of factors such as heavy loads, chemical exposure, and extreme temperatures. In addition to surface maintenance, it’s important to ensure that the underlying support structure of the grating is also in good condition. This includes checking for signs of corrosion or deterioration in the supporting beams, frames, and connections. By addressing any issues with the support structure, you can maintain the overall integrity and stability of the steel grating system.

In commercial and public spaces, steel grating is often used for walkways, platforms, and safety barriers. Regular maintenance is crucial for ensuring the safety of pedestrians, preventing slip and fall accidents, and maintaining the aesthetic appeal of the space. This includes regular cleaning to remove dirt, grease, and other contaminants that can create hazardous conditions. In addition, inspections should be conducted to check for any signs of wear, damage, or loose components. Any issues should be addressed promptly to prevent accidents and ensure compliance with safety regulations. By implementing a proactive maintenance plan, you can create a safe and inviting environment for employees, customers, and the public.

In summary, maintaining steel grating is essential for ensuring its longevity, safety, and performance. By implementing a proactive maintenance plan that includes regular cleaning, inspections, and repairs, you can prevent corrosion, extend the lifespan of the grating, and ensure a safe environment for employees and the public. Whether it’s in industrial facilities, commercial buildings, or public spaces, proper maintenance of steel grating is crucial for safety and efficiency.

Steel grating maintenance is a critical aspect of ensuring the longevity and performance of the grating system. By implementing a proactive maintenance plan that includes regular cleaning, inspections, and repairs, you can prevent corrosion, extend the lifespan of the grating, and ensure a safe environment for employees and the public. Whether it’s in industrial facilities, commercial buildings, or public spaces, proper maintenance of steel grating is crucial for safety and efficiency.

Regular cleaning is essential for maintaining steel grating and preventing corrosion. This can be done using a mild detergent, water, and a brush or pressure washer to remove dirt, debris, and other contaminants. In addition, inspections should be conducted to identify any signs of wear, damage, or corrosion. By addressing these issues early, you can prevent further damage and ensure the long-term performance of the steel grating.

In industrial settings, proactive maintenance is crucial for mitigating the impact of factors such as heavy loads, chemical exposure, and extreme temperatures on steel grating. This includes regular inspections, cleaning, and protective coatings to prevent corrosion and wear. Additionally, it’s important to ensure that the underlying support structure of the grating is also in good condition. By addressing any issues with the support structure, you can maintain the overall integrity and stability of the steel grating system.

In commercial and public spaces, regular maintenance of steel grating is essential for ensuring the safety of pedestrians and maintaining the aesthetic appeal of the space. This includes regular cleaning to remove dirt, grease, and other contaminants that can create hazardous conditions. In addition, inspections should be conducted to check for any signs of wear, damage, or loose components. By implementing a proactive maintenance plan, you can create a safe and inviting environment for employees, customers, and the public.

By addressing issues such as regular cleaning, inspections, and repairs, you can prevent corrosion, extend the lifespan of the grating, and ensure a safe environment for employees and the public. Proper maintenance of steel grating is crucial for safety and efficiency in industrial facilities, commercial buildings, and public spaces. Implementing a proactive maintenance plan is essential for ensuring the longevity and performance of the grating system.

Steel grating maintenance is essential for ensuring its longevity, safety, and performance. By implementing a proactive maintenance plan that includes regular cleaning, inspections, and repairs, you can prevent corrosion, extend the lifespan of the grating, and ensure a safe environment for employees and the public. Whether it’s in industrial facilities, commercial buildings, or public spaces, proper maintenance of steel grating is crucial for safety and efficiency.