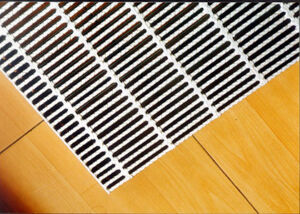

Narrow pitch grating for chemical plants is an essential component in the design and operation of industrial facilities. These gratings are specifically engineered to meet the unique needs of chemical processing environments, where safety and efficiency are paramount. By utilizing narrow pitch grating, plants can ensure optimal drainage, reduce the risk of slips and falls, and promote a safer working environment for all personnel.

One of the primary advantages of narrow pitch grating for chemical plants is its ability to provide superior drainage capabilities. In chemical processing facilities, spills and leaks can occur, making it crucial for the flooring system to manage liquids effectively. Narrow pitch gratings allow for quick drainage, minimizing the risk of hazardous materials pooling on the floor and creating dangerous conditions for workers.

In addition to enhanced drainage, narrow pitch grating offers a high level of slip resistance. Chemical plants often deal with wet and slippery surfaces due to spills, which can lead to accidents. The design of narrow pitch gratings incorporates features that provide traction, reducing the likelihood of slips and falls. This is particularly important in environments where employees are frequently moving between different areas of the plant.

Another significant benefit of narrow pitch grating is its durability. Chemical plants operate under harsh conditions, including exposure to corrosive substances and heavy machinery. The materials used in narrow pitch gratings are specifically chosen for their resistance to corrosion and wear, ensuring a long lifespan even in the most demanding environments. This durability translates into cost savings over time, as plants will spend less on maintenance and replacement.

তাছাড়া, narrow pitch grating can be customized to fit the specific needs of each chemical plant. Different processes may require varying sizes and configurations of gratings to accommodate equipment and workflow. Manufacturers of narrow pitch grating offer a range of options, allowing plant managers to select the ideal solution that meets both safety and operational requirements.

The installation of narrow pitch grating is another critical aspect to consider. Proper installation is essential to ensure that the grating functions as intended and provides the necessary safety features. Many companies that supply narrow pitch grating for chemical plants also offer installation services, ensuring that the product is fitted correctly and adheres to industry standards.

Maintenance of narrow pitch grating is also vital for its continued performance. Regular inspections should be conducted to identify any signs of wear or damage. This proactive approach to maintenance helps to prevent accidents and ensures that the grating continues to provide the necessary drainage and slip resistance. উপরন্তু, cleaning the gratings regularly will help maintain their effectiveness and longevity.

The choice of materials for narrow pitch grating is crucial in chemical plants. Common materials include stainless steel, fiberglass, and aluminum, each offering unique benefits. Stainless steel is known for its strength and corrosion resistance, making it ideal for harsh chemical environments. Fiberglass is lightweight and resistant to many chemicals, while aluminum provides a balance of strength and weight, making it suitable for various applications.

In recent years, there has been an increasing focus on sustainability within the chemical industry. Narrow pitch grating can contribute to this effort by being made from recycled materials or designed for easy recycling at the end of their life cycle. This aligns with the growing trend of environmentally friendly practices in manufacturing and operations, making narrow pitch grating an attractive option for forward-thinking chemical plants.

The regulatory landscape surrounding chemical plants is complex and ever-evolving. Compliance with safety standards and regulations is paramount for these facilities. Narrow pitch grating can help meet various safety regulations, as its design often includes features that enhance worker safety and reduce environmental impact. By investing in high-quality narrow pitch grating, chemical plants can demonstrate their commitment to safety and regulatory compliance.

Training employees on the importance of proper flooring systems, including narrow pitch grating, is essential. Workers should be educated about the role of these gratings in maintaining a safe work environment. Providing training and resources can empower employees to take responsibility for safety and be proactive in reporting any issues with the grating system.

As technology advances, so does the design and manufacturing of narrow pitch grating. New materials and fabrication techniques are constantly being developed, leading to improved performance characteristics. Chemical plants should stay informed about the latest innovations in grating technology to ensure they are utilizing the best possible solutions for their facilities.

The aesthetic aspect of narrow pitch grating should not be overlooked. While functionality is critical, the appearance of the flooring system can also impact the overall environment of the chemical plant. Manufacturers now offer a variety of finishes and colors for narrow pitch grating, allowing facilities to maintain a professional look while adhering to safety standards.

When selecting narrow pitch grating for chemical plants, it is essential to consider the specific requirements of the facility. Factors such as load-bearing capacity, chemical exposure, and foot traffic should all be taken into account. Consulting with experts in the field can provide valuable insights into the best choices for each unique situation.

উপসংহারে, narrow pitch grating for chemical plants is a vital component that enhances safety, efficiency, and durability. By understanding the benefits and considerations associated with this type of grating, plant managers can make informed decisions that contribute to the overall success of their operations. Investing in high-quality narrow pitch grating is not just a matter of compliance; it is an investment in the safety and well-being of all employees.

The future of narrow pitch grating in chemical plants looks promising as industries continue to prioritize safety and efficiency. With ongoing advancements in materials and design, the potential for improved performance and sustainability is vast. Chemical plants that adopt these innovations will likely see significant benefits in their operations, leading to a safer and more productive work environment.

As the chemical industry evolves, so too will the demands placed on flooring systems like narrow pitch grating. Staying ahead of these trends and adapting to new challenges will be crucial for the success of chemical plants in the years to come. By prioritizing safety and efficiency, facilities can ensure they remain competitive in an increasingly complex market.

Ultimately, the choice of narrow pitch grating for chemical plants is about more than just functionality; it’s about creating a culture of safety and responsibility. By investing in high-quality products and fostering a commitment to safety among employees, chemical plants can thrive in a challenging environment while protecting their most valuable asset: their workforce.