Elevator shafts are critical components in modern buildings, serving as the vertical transportation routes for people and goods. Among the various elements that ensure the safety and efficiency of elevator systems, narrow pitch grating for elevator shafts plays a vital role. This type of grating is specifically designed to provide a safe and stable surface for maintenance personnel, while also allowing for proper air circulation and light penetration in the shaft.

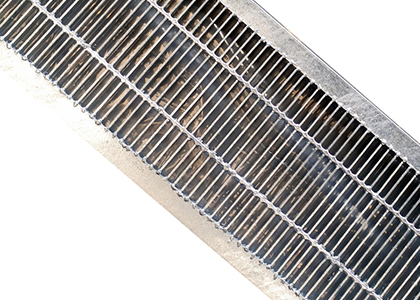

The design of narrow pitch grating for elevator shafts focuses on minimizing the gaps between the grating panels. This is essential not only for safety, preventing tools or personnel from falling through but also for maintaining the aesthetic appeal of the elevator system. The narrow pitch ensures that the grating can support the weight of maintenance workers and any equipment they may bring into the shaft, thereby enhancing overall safety.

One of the primary materials used in the production of narrow pitch grating is steel. Steel grating offers durability and strength, making it ideal for high-traffic areas such as elevator shafts. উপরন্তু, steel can be treated with anti-corrosive coatings to extend its lifespan, especially in environments where moisture is present. This treatment is crucial for maintaining the integrity of the grating over time, ensuring it remains a reliable safety feature.

Another popular material for narrow pitch grating is aluminum. Aluminum grating is lightweight yet strong, making it easier to handle during installation. It also has excellent resistance to corrosion, which is particularly beneficial in elevator shafts that may be exposed to varying humidity levels. The choice between steel and aluminum often depends on the specific requirements of the building and the expected load on the grating.

In addition to material selection, the manufacturing process of narrow pitch grating is also significant. The grating is typically fabricated through a process of welding or pressing, which creates a robust structure capable of withstanding heavy loads. This manufacturing process ensures that the grating is not only functional but also meets the necessary safety standards set forth by building codes and regulations.

Proper installation of narrow pitch grating for elevator shafts is crucial to its performance. Installation should be carried out by professionals who understand the specific requirements of elevator systems. This includes ensuring that the grating is securely fastened and that there are no gaps that could pose safety risks. Regular inspections should also be conducted to identify any wear or damage that may occur over time.

The maintenance of narrow pitch grating is another important aspect that building managers must consider. Regular cleaning is necessary to remove debris and ensure that the grating remains slip-resistant. উপরন্তু, periodic inspections can help identify any signs of corrosion or structural weakness, allowing for timely repairs or replacements. A proactive maintenance approach can significantly extend the lifespan of the grating.

Another benefit of narrow pitch grating is its contribution to the overall safety of elevator shafts. By providing a stable surface for maintenance personnel, it reduces the risk of accidents during routine inspections and repairs. This is particularly important in high-rise buildings where maintenance tasks may involve working at significant heights. Safety measures, including the use of harnesses and safety equipment, should always be implemented in conjunction with the use of grating.

Furthermore, narrow pitch grating can enhance the aesthetic appeal of elevator shafts. With various finishes and coatings available, building owners can choose grating that complements the overall design of the building. This is particularly relevant in commercial spaces where first impressions matter. A well-designed elevator shaft can contribute to the building’s branding and image, making it more appealing to tenants and visitors alike.

The use of narrow pitch grating for elevator shafts is not limited to just safety and aesthetics; it also plays a role in the functionality of the elevator system. By allowing for better airflow within the shaft, the grating helps regulate temperature and humidity levels, which can be beneficial for the elevator machinery. This can lead to improved efficiency and longevity of the elevator system, reducing the likelihood of costly repairs.

In terms of compliance, narrow pitch grating must meet various building codes and regulations. These standards are in place to ensure the safety and reliability of elevator systems. Building owners and managers should work closely with manufacturers to ensure that the grating they choose adheres to all relevant codes. This not only protects the safety of users but also shields the building owner from potential legal issues related to non-compliance.

The installation of narrow pitch grating can also affect the overall cost of elevator maintenance. While the initial investment may be higher for high-quality grating, the long-term savings associated with reduced maintenance and increased safety can be significant. উপরন্তু, the durability of the materials used can lead to fewer replacements over time, further justifying the upfront costs.

When selecting narrow pitch grating, it is essential to consider the specific needs of the elevator system. Factors such as the expected load, frequency of use, and environmental conditions should all be taken into account. Consulting with experts in the field can help ensure that the right type of grating is chosen for each unique situation, maximizing both safety and functionality.

উপসংহারে, narrow pitch grating for elevator shafts is a critical component that enhances safety, functionality, and aesthetics. Its design and material choices play a significant role in the overall efficiency of elevator systems. By investing in high-quality grating and ensuring proper installation and maintenance, building owners can protect both their investment and the safety of their tenants.

As technology continues to advance, the design and manufacturing processes of narrow pitch grating are also evolving. Innovations in materials and production techniques are leading to even more durable and efficient grating options. This ongoing development is essential for keeping up with the demands of modern architecture and the increasing expectations of safety and performance in building design.

The future of narrow pitch grating for elevator shafts will likely see a greater emphasis on sustainability. As more building owners seek eco-friendly solutions, manufacturers are exploring materials that are both durable and environmentally responsible. This shift towards sustainability can benefit not only the environment but also the reputation of building owners who prioritize green building practices.

In summary, narrow pitch grating for elevator shafts is an essential element that contributes to the safety, functionality, and aesthetics of modern buildings. By understanding its importance and investing in high-quality options, building owners can ensure the longevity and efficiency of their elevator systems. With proper maintenance and adherence to safety standards, narrow pitch grating can provide lasting benefits for years to come.

Ultimately, the choice of narrow pitch grating can significantly impact the overall performance of elevator systems. By prioritizing safety, functionality, and aesthetic appeal, building owners can create a positive experience for users while also safeguarding their investment. As the industry continues to evolve, staying informed about the latest trends and technologies will be crucial for making the best decisions regarding elevator shaft grating.