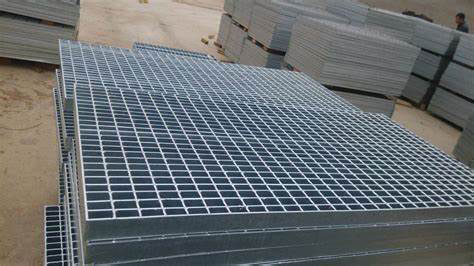

Pressed welded steel grating is a significant component in modern construction and industrial applications. It is fabricated through a meticulous process. The steel bars are first precisely cut and positioned. Then, they are pressed and welded together at their intersections. This welding technique ensures a firm and stable connection. The grating’s structure is designed to offer high strength and rigidity. It can bear substantial loads without deformation. For instance, in heavy-duty industrial flooring, it can support the weight of large equipment and heavy foot traffic. The open design of the grating also allows for proper ventilation and drainage, which is crucial in areas where moisture or gases need to be dissipated.

The manufacturing process of pressed welded steel grating demands strict quality control. The selection of raw materials is a key step. High-quality steel is chosen to guarantee the grating’s durability and performance. After the welding process, the grating undergoes a series of inspections. Visual inspections check for any welding defects or surface irregularities. Additionally, mechanical tests are conducted to assess its load-bearing capacity. Only those that meet the required standards are passed for further processing or installation. This attention to detail in manufacturing results in a reliable and long-lasting product.

In terms of applications, pressed welded steel grating is widely used. It is a common sight in industrial plants, where it serves as walkways, Ang steel grating panel ay partikular na idinisenyo para sa mataas na epekto, and stair treads. In chemical plants, its corrosion-resistant properties (achieved through proper surface treatments) make it suitable for handling corrosive substances. In the construction of bridges and overpasses, it provides a safe and durable surface for pedestrians and vehicles. It can also be used in drainage systems, allowing water to flow freely while preventing debris from clogging. The versatility of this grating makes it an essential element in many infrastructure and industrial projects.

Installation of pressed welded steel grating is relatively convenient. It can be customized to fit specific dimensions and shapes. It can be easily installed using bolts, clips, or welding, depending on the requirements of the project. The modular nature of the grating allows for quick assembly and disassembly, which is beneficial for maintenance and repair work. Moreover, its lightweight compared to some other materials makes it easier to handle during installation, reducing labor costs and installation time.

The durability and low maintenance requirements of pressed welded steel grating are also noteworthy. Once installed, it can withstand harsh environmental conditions for an extended period. It is resistant to rust, abrasion, and impact. Minimal maintenance is needed, usually just periodic cleaning to remove dirt and debris. This not only saves costs but also ensures the continuous and efficient operation of the facilities where it is installed. Overall, pressed welded steel grating is a reliable and practical choice for a wide range of engineering and construction needs.