Steel grating customization is a process that involves tailoring steel grating products to meet specific project requirements. This customization can include adjustments to size, shape, مواد, and surface treatment, among other factors. By offering customization options, steel grating manufacturers can provide solutions that are perfectly suited to the needs of their clients.

One of the key aspects of steel grating customization is the ability to tailor the product to the exact dimensions required for a particular project. This ensures a precise fit and optimal performance in the intended application. Whether it’s for industrial flooring, slippery مٿاڇري ۽ ٻين سخت ماحول, or trench covers, customized steel grating can be manufactured to the exact specifications provided by the customer.

In addition to size customization, there are also various options for the shape and design of steel grating. Different patterns, bar spacings, and load capacities can be tailored to ensure that the grating meets the specific structural and safety requirements of the project. This level of customization allows for the creation of highly specialized and effective grating solutions.

Material selection is another important aspect of steel grating customization. Depending on the environmental conditions and usage requirements, different materials such as carbon steel, بي داغ لوه, or aluminum may be chosen for the grating construction. Customization in material selection ensures that the grating will have the necessary strength, corrosion resistance, and durability for its intended application.

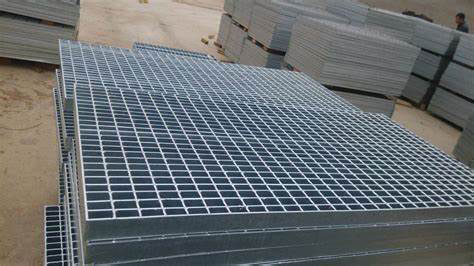

Surface treatment options also play a significant role in steel grating customization. Various coatings and finishes can be applied to the grating to enhance its performance and longevity. This includes processes such as galvanization, painting, or powder coating, which provide protection against corrosion, wear, and exposure to harsh elements. Customized surface treatments can further extend the lifespan of the grating.

When it comes to customization, the load capacity of steel grating is a critical consideration. By customizing the load bars and cross bars based on the anticipated loads and stresses, the grating can be optimized for strength and structural integrity. This ensures that it will safely support the required loads without compromising safety or performance.

Customized steel grating can also incorporate features such as nosing, toe plates, or edge banding to enhance safety and functionality in specific applications. These additional elements can be tailored to meet regulatory requirements and improve the overall usability of the grating in areas where foot traffic or wheeled equipment is present.

In the process of steel grating customization, collaboration between the manufacturer and the client is essential. Clear communication of project requirements, specifications, and performance expectations is crucial for achieving the desired customization outcomes. This collaborative approach ensures that the customized grating will effectively meet the functional and structural needs of the project.

Another benefit of steel grating customization is the ability to integrate branding, logos, or specific visual elements into the grating design. This allows for customized aesthetics that align with the client’s brand identity or project themes. Whether it’s for architectural purposes, corporate branding, or artistic installations, customized grating can be tailored to achieve the desired visual impact.

نتيجي ۾, steel grating customization offers a wide range of benefits for tailoring grating products to specific project requirements. From size and shape adjustments to material selection, surface treatments, and specialized features, customization enables the creation of highly tailored solutions. By leveraging customization options, clients can obtain steel grating products that are precisely suited to their functional, aesthetic, and performance needs.