Steel grating for beverage bottling plants plays a crucial role in ensuring the safety and efficiency of operations. These grates provide a durable and slip-resistant surface, essential in environments where liquid spills are common. The open grid design allows for efficient drainage, preventing the accumulation of liquids that could pose hazards to workers. Additionally, the robust construction of steel grating supports heavy equipment and foot traffic, making it an ideal choice for bottling plants.

In beverage bottling plants, hygiene is of utmost importance. Steel grating contributes to maintaining high sanitary standards by being easy to clean and resistant to corrosion. Stainless steel options are particularly beneficial, as they resist chemical reactions with cleaning agents commonly used in these facilities. The smooth surface of steel grating also prevents the buildup of bacteria and other contaminants, ensuring a clean environment for beverage production.

The installation of steel grating in beverage bottling plants is relatively straightforward, which minimizes downtime during maintenance or upgrades. Modular grating systems can be customized to fit specific areas within the plant, providing flexibility in design and installation. This adaptability ensures that the grating can accommodate various equipment layouts and production lines, enhancing the overall efficiency of the plant’s operations.

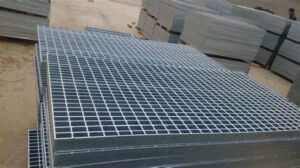

Steel grating for beverage bottling plants is available in several types, each suited to different needs. Welded steel grating is known for its strength and is ideal for areas with heavy machinery. Press-locked grating offers a smoother surface and is often used in areas where aesthetics are important. Riveted grating provides additional strength and durability, making it suitable for high-load applications.

The use of steel grating in beverage bottling plants also contributes to sustainability efforts. Steel is a recyclable material, and using it in construction reduces the environmental impact of the plant. Additionally, the durability of steel grating means that it has a long lifespan, reducing the need for frequent replacements and minimizing waste.

Safety is a primary concern in beverage bottling plants, and steel grating enhances workplace safety by providing a non-slip surface. This feature is particularly important in areas where liquids are frequently present, such as near filling stations and cleaning areas. The slip-resistant nature of steel grating helps prevent accidents, protecting workers and reducing the risk of injury.

The cost-effectiveness of steel grating for beverage bottling plants is another significant advantage. While the initial investment may be higher than other materials, the long-term benefits outweigh these costs. The durability and low maintenance requirements of steel grating lead to cost savings over time, making it a financially sound choice for plant managers.

Steel grating can also be designed to meet specific regulatory standards required in beverage bottling plants. Compliance with health and safety regulations is crucial, and steel grating can be manufactured to meet these standards, ensuring that the plant operates within legal requirements. This compliance helps avoid potential fines and enhances the plant’s reputation for safety and quality.

In addition to safety and hygiene, steel grating for beverage bottling plants enhances the overall workflow. The open design of the grating allows for easy movement of air and liquids, contributing to a more efficient production process. This feature is particularly beneficial in areas where temperature control is essential, as it helps maintain a consistent environment.

The aesthetic appeal of steel grating should not be overlooked. In beverage bottling plants where tours or client visits are common, the clean and professional appearance of steel grating can make a positive impression. The sleek finish of stainless steel grating adds a modern touch to the facility, reflecting the company’s commitment to quality and innovation.

Maintenance of steel grating in beverage bottling plants is relatively simple, requiring minimal effort to keep it in optimal condition. Regular cleaning with standard cleaning agents is usually sufficient to maintain its appearance and functionality. This ease of maintenance ensures that the grating continues to meet safety and hygiene standards without excessive downtime.

The versatility of steel grating makes it suitable for various applications within a beverage bottling plant. From walkways and platforms to drainage covers and mezzanine flooring, steel grating can be used throughout the facility. This versatility simplifies inventory management, as a single type of grating can serve multiple purposes.

Steel grating for beverage bottling plants also offers excellent load-bearing capabilities. This strength is essential for supporting the heavy machinery and equipment commonly found in bottling plants. The ability to withstand significant weight without deforming ensures that the grating remains functional and safe over time.

The customization options available for steel grating are extensive, allowing it to be tailored to the specific needs of a beverage bottling plant. Grating can be cut to size and fitted with additional features such as kick plates or toe boards to enhance safety. These customizations ensure that the grating meets the exact requirements of the plant’s operations.

The open design of steel grating facilitates the easy passage of air and light, contributing to a more pleasant working environment. This feature is particularly beneficial in areas where natural light is limited, as it helps brighten the space and improve visibility. Increased airflow also aids in ventilation, reducing the risk of mold and mildew growth.

Steel grating for beverage bottling plants can also be designed to reduce noise levels within the facility. By choosing grating with specific acoustic properties, plant managers can create a quieter working environment, enhancing worker comfort and productivity. This attention to detail demonstrates a commitment to employee well-being.

The installation of steel grating can also improve the energy efficiency of a beverage bottling plant. The open design allows for better air circulation, which can reduce the need for artificial heating and cooling. This improved energy efficiency can lead to significant cost savings over time, making steel grating an environmentally and economically beneficial choice.

In terms of durability, steel grating is unmatched. Its resistance to wear and tear ensures that it remains functional even in high-traffic areas. This durability reduces the need for frequent repairs or replacements, contributing to the overall cost-effectiveness of using steel grating in beverage bottling plants.

The corrosion resistance of steel grating is another important factor to consider. In environments where moisture and chemicals are present, such as beverage bottling plants, corrosion can be a significant concern. Steel grating, particularly when made from stainless steel, resists corrosion and maintains its integrity over time.

Finally, the use of steel grating in beverage bottling plants supports the overall operational efficiency of the facility. By providing a safe, durable, and hygienic surface, steel grating contributes to a smoother workflow and helps maintain high production standards. This efficiency ultimately leads to higher productivity and profitability for the plant.