Steel grating for military installations plays a crucial role in ensuring the safety and efficiency of various defense infrastructures. These gratings are designed to withstand extreme conditions and provide a durable solution for military needs. With the ability to support heavy loads and resist corrosion, steel gratings are essential for platforms, walkways, and secure perimeters in military bases.

The design specifications of steel grating for military installations are stringent, ensuring they meet the high standards required for defense applications. These specifications include load-bearing capacity, corrosion resistance, and adaptability to various environments. Engineers often customize these gratings to fit specific military requirements, ensuring optimal performance under different operational conditions.

One of the primary applications of steel grating in military installations is in the construction of secure perimeters. These gratings provide a robust barrier that is difficult to breach, enhancing the security of sensitive areas. Additionally, they are often used in the construction of elevated platforms and walkways, allowing for easy access and movement of personnel and equipment.

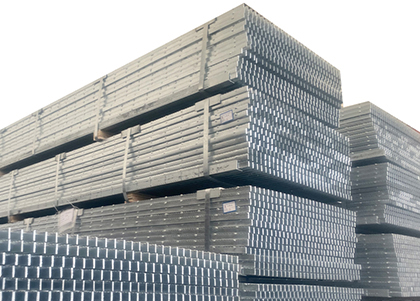

Corrosion resistance is a key feature of steel grating used in military installations. Given the diverse and often harsh environments where military bases are located, the materials used must withstand exposure to elements such as saltwater, chemicals, and extreme temperatures. Galvanized steel is commonly used to enhance the longevity and durability of these gratings.

The versatility of steel grating makes it suitable for a wide range of military applications. From aircraft hangars to vehicle maintenance facilities, these gratings provide a stable and durable surface that can support heavy machinery and equipment. Their open-grid design allows for efficient drainage, preventing water accumulation and reducing slip hazards.

In addition to their functional benefits, steel gratings also contribute to the safety of military personnel. By providing a stable and secure footing, they reduce the risk of accidents and injuries, especially in high-traffic areas. The non-slip surface of these gratings is particularly important in environments where quick and safe movement is critical.

Steel grating for military installations also plays a role in camouflage and concealment strategies. By integrating these gratings into the landscape, military engineers can create structures that blend seamlessly with the environment, reducing visibility to potential adversaries. This feature is particularly valuable in forward operating bases and other tactical locations.

The installation process of steel grating in military settings is designed to be quick and efficient. Pre-fabricated panels can be rapidly deployed, minimizing downtime and ensuring that critical infrastructure is operational as soon as possible. This efficiency is vital in situations where time is of the essence, such as during the establishment of temporary bases.

Maintenance of steel grating in military installations is relatively straightforward, thanks to the durability and corrosion resistance of the materials used. Regular inspections and cleaning are usually sufficient to ensure the gratings remain in optimal condition. This low maintenance requirement is an important factor in reducing operational costs and resource allocation.

The use of steel grating in military installations is not limited to ground-based applications. These gratings are also employed in naval and airborne platforms, where their lightweight and durable properties are particularly advantageous. In maritime settings, for example, steel gratings are used in the construction of decks and walkways on ships and submarines.

In airborne applications, steel gratings are used in the construction of hangars and maintenance facilities for aircraft. Their ability to support heavy loads and resist environmental factors makes them ideal for these settings, where safety and reliability are paramount. The open-grid design also facilitates the rapid drainage of fluids, which is essential in aircraft maintenance operations.

The environmental impact of steel grating for military installations is another consideration for defense planners. While steel production involves significant energy consumption, the longevity and recyclability of steel gratings help mitigate their environmental footprint. Many military installations prioritize the use of sustainable materials, and steel gratings fit well within these initiatives.

The adaptability of steel grating is demonstrated in its use across various branches of the military. Whether in the Army, Navy, Air Force, or Marine Corps, these gratings provide a consistent and reliable solution for infrastructure needs. Their versatility ensures they can be tailored to meet the specific demands of each branch, enhancing operational efficiency.

Innovation in steel grating technology continues to advance, with new materials and manufacturing techniques being developed to enhance performance. For military installations, these innovations can lead to improved durability, reduced weight, and enhanced corrosion resistance, all of which are critical for maintaining a strategic advantage.

The cost-effectiveness of steel grating is another factor that makes it an attractive option for military installations. While the initial investment may be significant, the long-term savings in maintenance and replacement costs make steel gratings a financially sound choice. This cost-benefit analysis is an important consideration for military budget planners.

The role of steel grating in military logistics cannot be overstated. From facilitating the movement of supplies to providing secure storage areas, these gratings are integral to the efficient operation of military bases. Their ability to support heavy loads and withstand harsh conditions ensures that logistical operations run smoothly and without interruption.

Safety standards for steel grating used in military installations are rigorous, ensuring that they meet the highest levels of quality and performance. These standards are essential for protecting the lives of military personnel and ensuring the integrity of defense infrastructure. Compliance with these standards is a top priority for manufacturers and military engineers alike.

The future of steel grating in military installations looks promising, with ongoing research and development aimed at enhancing their capabilities. As military operations become increasingly complex and diverse, the demand for robust and versatile infrastructure solutions like steel grating is expected to grow. This trend highlights the importance of continued investment in this critical area.

Collaboration between military engineers and steel grating manufacturers is key to developing solutions that meet the unique needs of defense applications. By working together, these stakeholders can ensure that the latest innovations in grating technology are effectively integrated into military infrastructure, enhancing both performance and security.

In conclusion, steel grating for military installations is an indispensable component of modern defense infrastructure. Its durability, versatility, and cost-effectiveness make it an ideal choice for a wide range of applications, ensuring the safety and efficiency of military operations around the world.