In the world of industrial materials, steel gratings and galvanized steel gratings are two important options that offer distinct characteristics and advantages.

Steel Grating

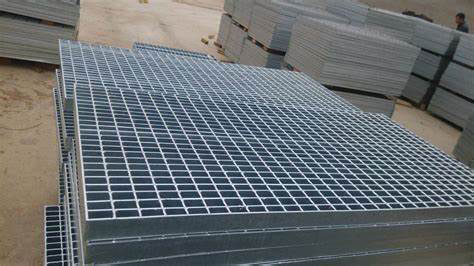

Steel grating is a commonly used material in various industries due to its strength and durability. It is made by welding or pressing steel bars together to form a grid-like structure. This open design allows for ventilation, drainage, and light penetration, making it suitable for applications such as walkways, platforms, and stair treads.

One of the main advantages of steel grating is its high load-bearing capacity. It can withstand heavy weights and is often used in industrial settings where large machinery and equipment are present. Additionally, steel grating is relatively easy to install and can be cut and shaped to fit specific requirements.

However, steel grating is susceptible to corrosion over time, especially in harsh environments. Exposure to moisture, chemicals, and other corrosive elements can cause the steel to rust and deteriorate, reducing its lifespan and safety.

Galvanized Steel Grating

Galvanized steel grating is steel grating that has been coated with a layer of zinc through a galvanizing process. This coating provides excellent protection against corrosion, making it highly suitable for outdoor and corrosive environments.

The galvanizing process forms a barrier between the steel and the surrounding environment, preventing moisture and oxygen from reaching the metal surface. This significantly extends the lifespan of the grating and reduces maintenance costs.

Galvanized steel grating also has the same strength and load-bearing capacity as regular steel grating. It offers the same ventilation and drainage benefits and can be installed in a similar manner.

In addition to its corrosion resistance, galvanized steel grating has a more aesthetically pleasing appearance compared to plain steel grating. The shiny zinc coating gives it a clean and professional look, which can be important in certain applications.

Comparison

When comparing steel grating and galvanized steel grating, the main difference lies in their corrosion resistance. Galvanized steel grating is clearly superior in this regard, offering long-term protection against the elements.

However, galvanized steel grating may be slightly more expensive than plain steel grating due to the additional coating process. This cost difference should be weighed against the longer lifespan and reduced maintenance requirements of galvanized grating.

In terms of strength and load-bearing capacity, both types of grating are generally comparable. The choice between them will depend on the specific application and environmental conditions.

If the grating will be exposed to moisture, chemicals, or other corrosive substances, galvanized steel grating is the better choice. On the other hand, if cost is a major consideration and the environment is relatively benign, plain steel grating may be sufficient.

In conclusion, steel grating and galvanized steel grating each have their own advantages and disadvantages. Understanding these differences can help in making an informed decision when choosing the right grating for a particular application. Whether it’s for a industrial facility, a construction site, or any other setting, the choice between steel grating and galvanized steel grating depends on factors such as corrosion resistance, cost, and strength requirements.