Steel grating and heavy-duty grating are both widely used in industrial and commercial applications. While they may seem similar, there are several key differences between the two types of grating that are important to consider when choosing the right option for your project.

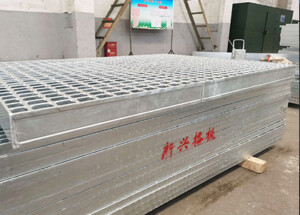

Steel grating is constructed using flat, horizontal bars that are spaced closely together. This design allows for the efficient drainage of water, oil, and other liquids, making it ideal for use in areas where slip resistance is a priority. On the other hand, heavy-duty grating is made from thicker, heavier bars that are spaced further apart. This design provides added strength and durability, making it suitable for applications where heavy loads and extreme conditions are a concern.

In terms of load capacity, heavy-duty grating is the clear winner. Its thicker bars and greater spacing allow it to support heavier loads without the risk of sagging or bending. This makes it the preferred choice for areas with high foot traffic, heavy machinery, or large vehicles. Steel grating, while still strong and durable, is better suited to lighter loads and pedestrian areas.

When it comes to cost, steel grating is often the more economical option. Its lighter weight and simpler construction make it easier to manufacture and install, resulting in lower overall costs. Heavy-duty grating, on the other hand, requires more material and labor to produce, making it a more expensive choice upfront.

Another important factor to consider is the level of security and safety provided by each type of grating. Steel grating, with its closely spaced bars, offers excellent slip resistance and is well-suited to areas where preventing accidents is a priority. Heavy-duty grating, with its larger openings, may not provide the same level of slip resistance and should be used with caution in areas where safety is a concern.

In terms of maintenance, both types of grating require regular cleaning and upkeep to ensure optimal performance and longevity. However, heavy-duty grating may be more prone to the buildup of debris and other materials due to its larger openings, requiring more frequent maintenance to prevent clogging and other issues.

In conclusion, the choice between steel grating and heavy-duty grating ultimately depends on the specific needs and requirements of your project. Consider factors such as load capacity, cost, safety, and maintenance when making your decision to ensure that you select the right type of grating for the job.