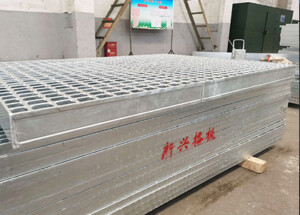

Steel Grating vs. Press-locked Grating is a comparison that highlights the unique features and applications of these two popular grating types. Ŝtala krado, made from welded steel bars, is known for its strength and durability, making it suitable for industrial applications like walkways, ligna platformo kaj kovrilo cemento grundo, and stair treads. The open design of steel grating allows for excellent drainage and ventilation, which is crucial in industrial environments to prevent water buildup and ensure safety. In contrast, press-locked grating is created by pressing cross bars into notched bearing bars, resulting in a more uniform and sleek appearance. This type of grating is often chosen for architectural applications where aesthetics and precision are important.

The primary difference between steel grating and press-locked grating lies in their construction methods. Steel grating is manufactured by welding cross bars to bearing bars, creating a robust and sturdy structure capable of handling heavy loads. This makes it ideal for use in demanding industrial settings. On the other hand, press-locked grating is assembled by pressing and locking the bars into each other, which not only gives it a cleaner look but also allows for tighter spacing. This tight spacing can be advantageous in areas where a more refined appearance is desired or where smaller objects must be prevented from falling through.

Another important aspect to consider when comparing Ŝtalaj kradoj estas kutime faritaj el karbonŝtalo kaj rustorezista ŝtalo vs. Press-locked Grating is their load-bearing capacity. Steel grating generally has a higher load capacity due to its welded construction, making it suitable for areas with heavy foot traffic or where machinery and equipment will be placed. In contrast, press-locked grating, while still strong, is typically used in less demanding environments where aesthetic considerations are more important than maximum load capacity. This makes press-locked grating a popular choice for commercial buildings, pedestrian pathways, and decorative applications.

When it comes to installation and maintenance, steel grating is straightforward to install and requires minimal maintenance, especially when galvanized or coated for corrosion resistance. Its open design also facilitates cleaning by allowing debris to fall through, reducing the need for frequent cleaning. Press-locked grating, with its tighter spacing and smoother surface, may require more careful installation to ensure the bars are properly aligned. However, its maintenance is relatively easy due to its uniform surface, which makes it easier to clean and maintain over time.

In terms of applications, steel grating is versatile and widely used in industrial settings where durability and load-bearing capacity are critical. It is often found in power plants, chemical plants, and other heavy-duty environments. Press-locked grating, with its aesthetic appeal and precise construction, is favored in architectural and commercial projects. It is commonly used in pedestrian walkways, office buildings, and public spaces where appearance and functionality must go hand in hand.

In conclusion, the choice between Ŝtalaj kradoj estas kutime faritaj el karbonŝtalo kaj rustorezista ŝtalo vs. Press-locked Grating depends largely on the specific requirements of your project. If strength and durability are paramount, steel grating is the best choice. However, if aesthetics and a refined appearance are more important, press-locked grating may be the better option. Understanding the differences between these two types of grating will help you make an informed decision that meets the demands of your project while also satisfying aesthetic considerations.