Trench covers play a crucial role in various industries and construction projects. They are designed to provide safety and protection while allowing access to underground utilities and spaces. In this article, we will explore the different types of trench covers available in the market.

Types of Trench Covers

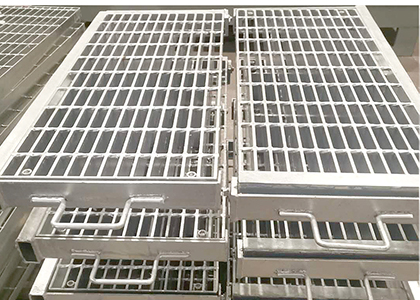

Steel Trench Covers

Steel trench covers are one of the most common types. They are known for their durability and strength. Made from high-quality steel, these covers can withstand heavy loads and are suitable for industrial and commercial applications.

Features of steel trench covers include corrosion resistance, easy installation, and long service life. They come in different sizes and thicknesses to meet various load requirements.

Steel trench covers are often used in areas where heavy machinery or vehicles pass, such as factories, warehouses, and construction sites.

Composite Trench Covers

Composite trench covers are made from a combination of materials, such as fiberglass and resin. These covers offer several advantages over traditional materials.

One of the main benefits of composite trench covers is their lightweight nature. This makes them easy to handle and install, reducing labor costs and time.

They also have excellent corrosion resistance and are resistant to chemicals and UV rays. Composite trench covers are available in a variety of colors and designs, making them aesthetically pleasing.

These covers are suitable for a wide range of applications, including residential areas, parks, and sidewalks.

Cast Iron Trench Covers

Cast iron trench covers have been used for many years and are known for their durability and strength. They are made by pouring molten iron into molds, resulting in a heavy-duty cover.

Cast iron covers are often decorated with patterns or designs, adding an aesthetic touch to the surroundings. They are also available in different sizes and load ratings.

However, cast iron covers are relatively heavy and may require special equipment for installation. They are commonly used in historical areas or where a traditional look is desired.

Plastic Trench Covers

Plastic trench covers are becoming increasingly popular due to their lightweight, cost-effective, and easy-to-install nature. They are made from high-density polyethylene (HDPE) or other durable plastics.

Plastic covers are resistant to corrosion, chemicals, and UV rays. They are available in different colors and can be customized with logos or markings.

These covers are suitable for light to medium load applications, such as residential driveways, gardens, and small commercial areas.

Factors to Consider When Choosing Trench Covers

Load Capacity

Determine the expected load that the trench cover will need to support. This includes vehicles, pedestrians, or heavy machinery. Choose a cover with an appropriate load rating to ensure safety.

Corrosion Resistance

Consider the environment in which the trench cover will be installed. If it will be exposed to moisture, chemicals, or salt, choose a cover with good corrosion resistance.

Aesthetics

Some applications may require trench covers that are aesthetically pleasing. Consider the design and color options available to match the surrounding area.

Installation and Maintenance

Evaluate the ease of installation and maintenance of the trench cover. Look for covers that are easy to install and require minimal maintenance.

In conclusion, there are several different types of trench covers available, each with its own unique features and advantages. When choosing a trench cover, consider factors such as load capacity, corrosion resistance, aesthetics, and installation/maintenance requirements. By selecting the right trench cover, you can ensure safety and functionality while also enhancing the appearance of the area.