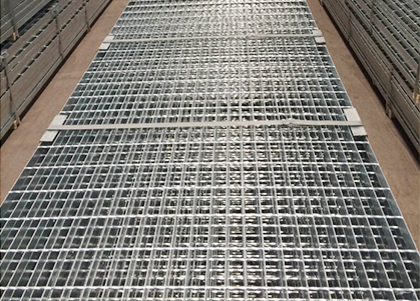

Steel grating and aluminum grating are two popular types of grating used in various industries. They have several key differences in terms of material, strength, and application.

Steel grating is made of carbon steel, which is known for its strength and durability. It is commonly used in industrial flooring, catwalks, мезонины, and stair treads. On the other hand, aluminum grating is made of aluminum alloy, which is lightweight and corrosion-resistant. It is often used in environments where corrosion resistance is a priority, such as water and wastewater treatment plants, chemical processing facilities, and marine applications.

One of the main differences between steel grating and aluminum grating is their weight. Steel grating is much heavier than aluminum grating, which makes it more suitable for applications that require high strength and load-bearing capacity. Aluminum grating, on the other hand, is lighter and easier to install, making it ideal for projects where weight is a concern.

Another important difference is their corrosion resistance. Steel grating is susceptible to rust and corrosion, especially in harsh environments or when exposed to chemicals. In contrast, aluminum grating offers excellent corrosion resistance, making it a preferred choice for outdoor and corrosive environments.

When it comes to maintenance, steel grating requires regular painting or coating to prevent rust and corrosion, while aluminum grating is virtually maintenance-free due to its natural corrosion resistance. This can result in cost savings over the lifetime of the grating.

Furthermore, steel grating has a higher strength and load-bearing capacity compared to aluminum grating. This makes steel grating the preferred choice for heavy-duty applications where strength and durability are crucial.

Despite these differences, both steel grating and aluminum grating have their unique advantages and are suitable for different applications. The choice between the two depends on factors such as the environment, load requirements, maintenance considerations, and budget constraints.

In conclusion, steel grating and aluminum grating differ in terms of material, weight, corrosion resistance, maintenance, and strength. Understanding these differences is essential for selecting the right type of grating for a specific application.