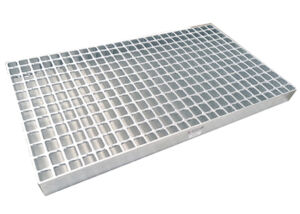

Hot-dip galvanizing is an essential process for steel grating to prevent corrosion and extend its lifespan.

The process involves immersing the steel grating in molten zinc, which creates a metallurgical bond that provides superior protection against rust and corrosion.

One of the key reasons why hot-dip galvanizing is important for steel grating is its ability to withstand harsh environmental conditions, including exposure to moisture, chemicals, and extreme temperatures.

The protective coating formed during the galvanizing process acts as a barrier, shielding the steel grating from corrosive elements and preventing the formation of rust.

In addition to corrosion resistance, hot-dip galvanizing also enhances the mechanical properties of steel grating, making it more durable and resilient.

The zinc coating adds an extra layer of protection, making the steel grating suitable for outdoor applications such as walkways, platforms, and industrial flooring.

Furthermore, hot-dip galvanized steel grating requires minimal maintenance, reducing the need for costly repairs and replacements over time.

The longevity and cost-effectiveness of galvanized steel grating make it a preferred choice for various industries, including construction, manufacturing, and infrastructure.

Another important aspect of hot-dip galvanizing for steel grating is its environmental sustainability.

The process is known for its minimal environmental impact, as it produces no harmful emissions and utilizes natural resources efficiently.

By choosing hot-dip galvanized steel grating, companies can contribute to sustainable practices and reduce their carbon footprint.

The versatility of galvanized steel grating makes it suitable for a wide range of applications, from industrial facilities to public infrastructure projects.

Its high strength-to-weight ratio and anti-slip properties make it ideal for safety-critical environments such as oil rigs, chemical plants, and wastewater treatment plants.

Hot-dip galvanized steel grating also offers aesthetic appeal, with its shiny and uniform finish that complements modern architectural designs.

The durability and visual appeal of galvanized steel grating make it a popular choice for architects, engineers, and designers.

In conclusion, hot-dip galvanizing plays a crucial role in enhancing the performance, longevity, and sustainability of steel grating, making it an indispensable solution for various industrial and infrastructure applications.